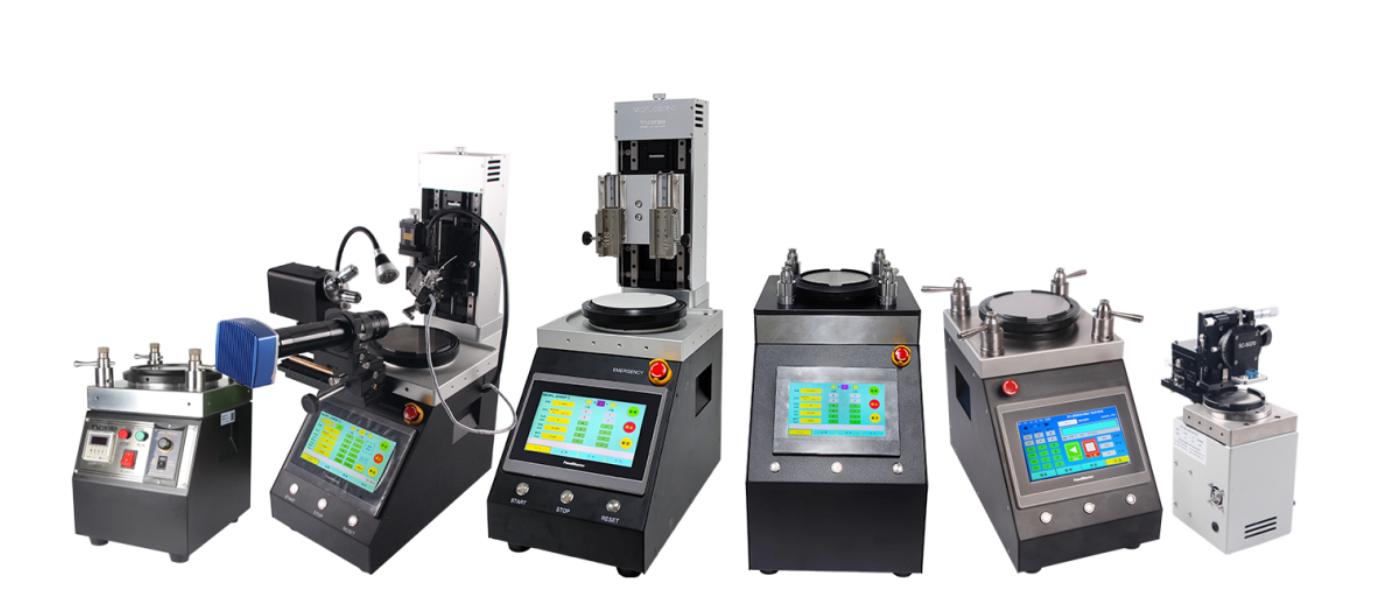

Precision Meets Versatility: Selecting a Fiber Polishing Machine for All Connectors

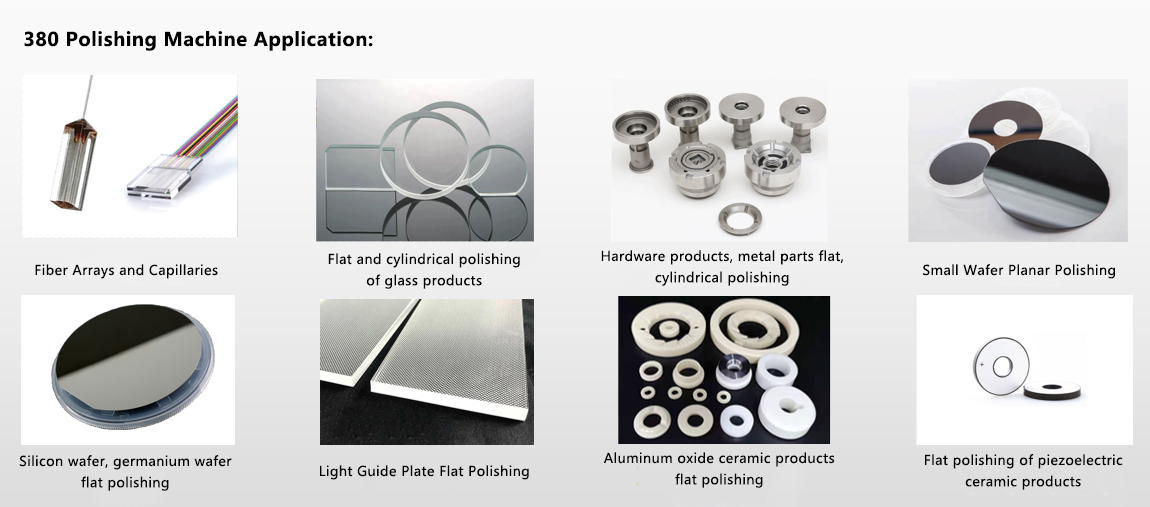

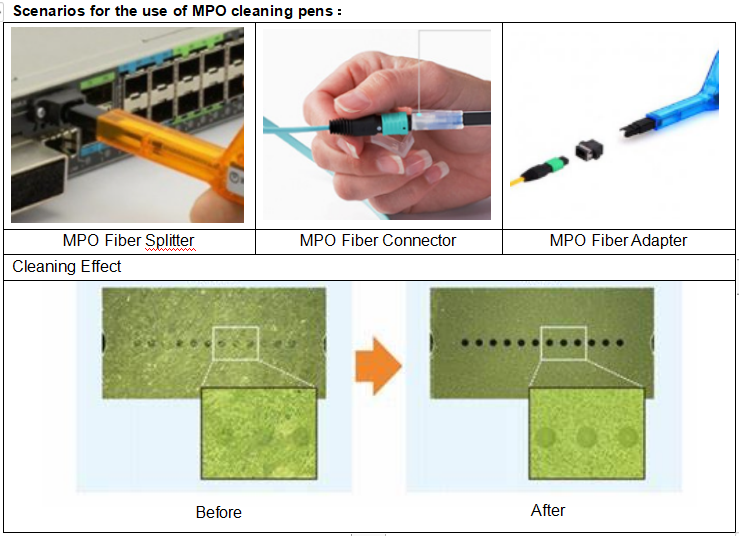

In the manufacturing of fiber optic patch cords and during network deployment and maintenance, selecting a polishing machine that offers both high polishing precision and compatibility with multiple connector types (such as LC/SC/FC/MPO, etc.) is crucial for enhancing efficiency and ensuring connection quality. The selection process should focus on two core criteria: “multi-type compatibility” and “high-precision control,” combining technical specifications with actual operational requirements for a comprehensive evaluation.

【View details】