Fiber Array Unit(FAU)Polishing & Inspection Solution

I、FA Component Applications

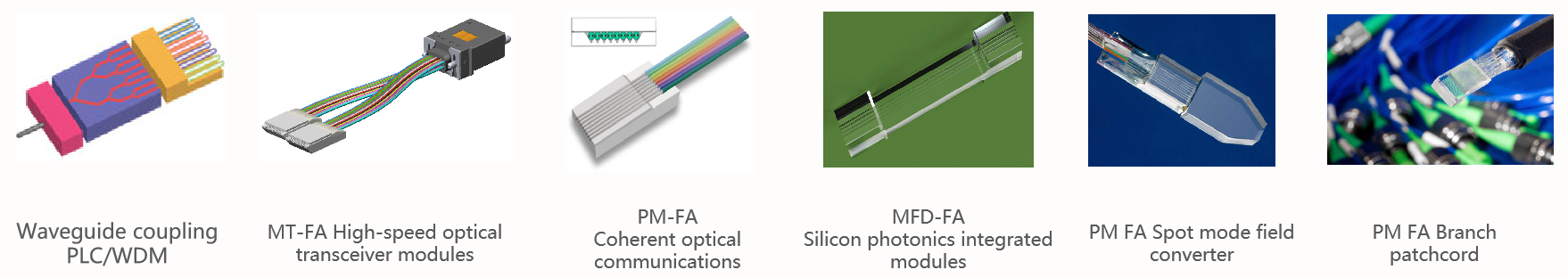

The FA (Fiber Array) component, also known as FAU (Fiber Array Unit), is a precision optical device that integrates multiple optical fibers. Through its array configuration, it enables efficient optical signal coupling and transmission.

Main Applications: Waveguide coupling for PLC/WDM devices, MT-FA components for high-speed optical transceiver modules, PM-FA for coherent optical communications, and MFD-FA for silicon photonics integrated modules.

II、Common FA End-face Polishing Methods-1

Two-step Polishing Method – 380 machine ring polishing + counterweight pressure polishing fixture.

Two-step Polishing Method Includes :Rough polishing and Fine polishing.

Advantages:

- Suitable for high-volume precision polishing;

- Simultaneously accommodates three polishing fixtures for high throughput;

- Two-step process with selectable grinding/polishing solution;

- Equipped with a timing accumulation function, allowing polishing time to be set in hh/mm/ss;

- Achieves <0.005mm surface flatness on 50mm-diameter polishing planes post-processing.

II、Common FA End-face Polishing Methods-2

Four-step Polishing Method: Use a doursquare pressure polishing machine with a ferrule rebound polishing fixture

Four-step Polishing Method Includes :glue removal、rough polishing、fine polishing、final polishing.

Advantages:

- Ideal for small-batch precision polishing and R&D applications;

- Short cycle time per process with high polishing efficiency;

- Pre-programmable polishing parameters enable operator-independent operation;

- High process tolerance with adjustable parameters (time/pressure) for multi-stage correction based on ferrule conditions;

- Optimal cost-efficiency ratio with polishing machine/consumables compatibility and simplified maintenance.

II、Common FA End-face Polishing Methods-3

Two-step Polishing Method – 203 flat swing polishing machine +digital display of polishing amount polishing fixture.

The Two-step Polishing Method Includes: 3um rough polishing and 0.5um polishing.

Advantages:

- Suitable for precision polishing of products, resulting in a flatter polishing surface;

- Suitable for single V-groove bonding FA polishing , with polishing fixtures that monitor polishing height;

- A comprehensive control system, including disc speed, swing arm settings, and feed rate;

- Time setting range: 0–10 hours. The machine automatically stops when the material processing is complete. In polishing mode, the alarm sounds but the machine does not stop, eliminating the need for operator supervision;

- The polishing fixture is easy to disassemble, enabling quick switching between grinding and polishing processes, making it suitable for polishing in environments with limited space.

III、FA End-face Inspection Equipment(1/5)

Name: FA/Capillary Size Angle Automatic Measuring Instrument

Model:ATS-FA5X

Function: Automatically measures FA/capillary dimensions and angles, stores data reports

Key Features:

- Specially designed for measuring the size and angle of FA or glass capillary;

- Magnifier options: 2.5x/5x/10x;

- Length measurement accuracy: 0.001 mm;

- angle measurement resolution: 0.001 degrees;

- Built-in adjustable light source up and down ensures clear imaging;

- Automatically determines “OK” or “NG” and generates reports and stores measurement data.

III、FA External Size Inspection Equipment(2/5)

Name:Two-Dimensional Image Measuring Machine

Model:VMS-3020

Function: Measure FA/FAU external dimensions

Key Features:

- Multi-language interface for seamless switching, catering to the needs of customers from different countries;

- Capable of recording user programs, editing commands, and teaching execution;

- Fully featured with large-map navigation, specialized 3D rotating lights for tooling and molds, 3D scanning systems, rapid automatic focusing, and automatic zoom magnifier;

- Multi-point measurement of points, lines, circles, arcs, ellipses, and rectangles with high measurement accuracy;

- Combined measurement functions including center point construction, intersection point construction, line construction, circle construction, angle construction, coordinate translation, and coordinate alignment, enhancing measurement efficiency.

III、FA Polarization Maintaining Alignment Measurement Equipment(3/5)

Name:FA Polarization Maintaining Alignment Measurement Equipment

Model:PMF-421P-FA-AT

Function:FA/FAU Panda Eye angle measurement, end-face inspection

Key Features:

- Specifically designed for FA fiber array alignment, enabling precise measurement of polarization-maintaining fiber alignment angles and efficient alignment;

- Optional single-magnification or multi-magnification magnifier, with selectable trigger-based measurement mode or continuous measurement mode;

- Equipped with angle measurement functionality, enabling real-time detection of alignment angle deviations, with measurement recognition accuracy of 0.001°;

- Internal and external light sources ensure clear imaging of the end-face of polarization maintaining fibers;

- 600x500mm optical platform facilitates system expansion, with optional online heating curing or UV curing functions;

- Rotator adjustable from 0 to 360 degrees;

- Automatically determines “OK” or “NG” and generates reports while storing measurement data.

III、FA End-face inspection equipment(4/5)

Name: Triple Adjustable Multifunctional Fiber Inspection Scope

Model:FK3-421P-FA

Function: Measurement of FA end-face quality

Key Features:

- Three magnification levels are available simultaneously to achieve optimal efficiency and performance;

- Capable of detecting up to 128-core FA fiber arrays;

- Professionally designed clamping fixtures that do not damage the tested object;

- Clamping fixtures can be customized to different angles such as 0°, 6°, 8°, 10°, and 45°;

- Long service life with internal LED lighting bulbs lasting up to 100,000 hours;

- Built-in CCD camera for inspecting the end-face of fibers transmitting laser light, with an optional black-and-white monitor available.

III、FA End-face inspection equipment(5/5)

Name: Double Magnification Fiber Inspection Scope

Model:FK4-420P-FA

Function: Measurement of FA end-face quality

Key Features:

- Magnification ratio of 400x/80x;

- Suitable for FA, single-core capillary tubes, ceramic ferrules, MT ferrules, and MPO connector end-face inspection;

- Dual optical path imaging with adjustable brightness, revealing defects clearly;

- Touch-sensitive dual magnification image switching switch;

- Optional dual-screen display for viewing end-face imaging at two magnifications.

IV. Common Issues and Optimization Measures

| Issues type | Specific manifestations | Possible causes | Optimization measures |

| Fiber end-face damage | Scratches, cracks, and microcracks appear on the end-face. | 1. Polishing sandpaper/sheets contain impurities or particles have fallen off.

2. Polishing pressure is uneven (locally excessive). 3. Polishing solution is contaminated or insufficiently concentrated. 4. Equipment vibration or unstable rotation speed. |

1. Use imported high-precision sandpaper, and clean the polishing fixture and sandpaper before polishing.

2. Use stepwise pressure control (rough polishing 100-150g → fine polishing 50-80g), and regularly calibrate the equipment pressure uniformity. 3. Use high-purity deionized water to dilute the polishing solution , and replace it for each batch. 4. Install the equipment on a shock-absorbing base, and regularly maintain the motor speed stability. |

| Insufficient end-face flatness | Uneven end-face, collapsed edges, roughness exceeding standards | 1. Polishing steps missing or insufficient time

2. Fiber array not securely fixed 3. Polishing pad aged or unevenly worn 4. Differences in fiber material hardness |

1. Strictly follow the stepwise grinding process (rough polishing → medium polishing→ fine polishing), and control the polishing time based on particle size (e.g., 5–8 minutes for fine polishing).

2. Use vacuum adsorption or epoxy resin curing to fix the array, and add support blocks at the bottom. 3. Replace the polishing pad after every 50 polishing cycles, and inspect the surface flatness before use. 4. Test the hardness of the fiber optic cable by batch and adjust the polishing pressure parameters accordingly. |

Summary

The polishing of FA fiber arrays is a critical step in their manufacturing process. By precisely controlling the polishing process parameters, the optical performance and reliability of the FA fiber array can be effectively ensured. The polishing process involves equipment operation, selection of polishing consumables, and training of operators. Only well-trained technical personnel can ensure that operational details are executed properly. Ultimately, this leads to the standardization and streamlining of the production process. During production, it is necessary to procure some essential tooling and testing equipment to effectively enhance the consistency of mass production operations and improve production efficiency.