SC waterproof connector Polishing Solution

SC waterproof connector Polishing Solution

Program Description:

SC waterproof connector Polishing Solution for a variety of different applications.SC waterproof connector polishing in the engineering industry, optical communications, military communications, aerospace, emergency repair, underwater communications, marine industry, field wiring and other fields are widely used in harsh conditions harsh environment wiring, for temporary wiring and may be often stowed in the use of the situation. Ltd. has 15 years of experience in designing and grinding, waterproof head grinding jig can be customized, with the advantages of efficient grinding, high reliability and good stability.

Applicable products: SC, FC, LC, ST and other waterproof connector /patch cord polishing.

Applicable fields: engineering industry, optical communications, military communications, aerospace, emergency repair, underwater communications, marine industry, field wiring and other fields are widely used for harsh conditions harsh environment wiring, outdoor, waterproof, for temporary wiring and may be often put away to use the situation.

SC waterproof connector polishing Configuration:

| No. | Product Name | Model | Unit | Qty |

| 1 | Automatic Cable Cutting Machine | AOFC-2001 | 1 | Set |

| 2 | Sheath Stripping Machine | ASM-3 | 2 | Set |

| 3 | Tight Packing Stripping Machine | BSM-900 | 1 | Set |

| 4 | Mechanical Manual Dispenser | EIM-200 | optional | Set |

| 5 | Digital Manual Dispenser | EIM-500 | optional | Set |

| 6 | Automatic Dispenser | AEIM-500 | 1 | Set |

| 7 | Fiber Curing Oven | OFO-2000 | optional | Set |

| 8 | Economical Curing Oven | OFO-2001 | 8 | Set |

| 9 | Lever type crimping machine | FCCM-3000A | optional | Set |

| 10 | Vertical Crimping Machine | FCCM-2001 | 4 | Set |

| 11 | Electric Crimping Machine | FCCM-4001 | optional | Set |

| 12 | 1 ton crimping machine | FCCM-5000A | optional | Set |

| 13 | Four corners pressurized grinding machine | NEOPL-2000A | 6 | Set |

| 14 | Programmable four-corner pressurized grinder | NEOPL-2000P | optional | Set |

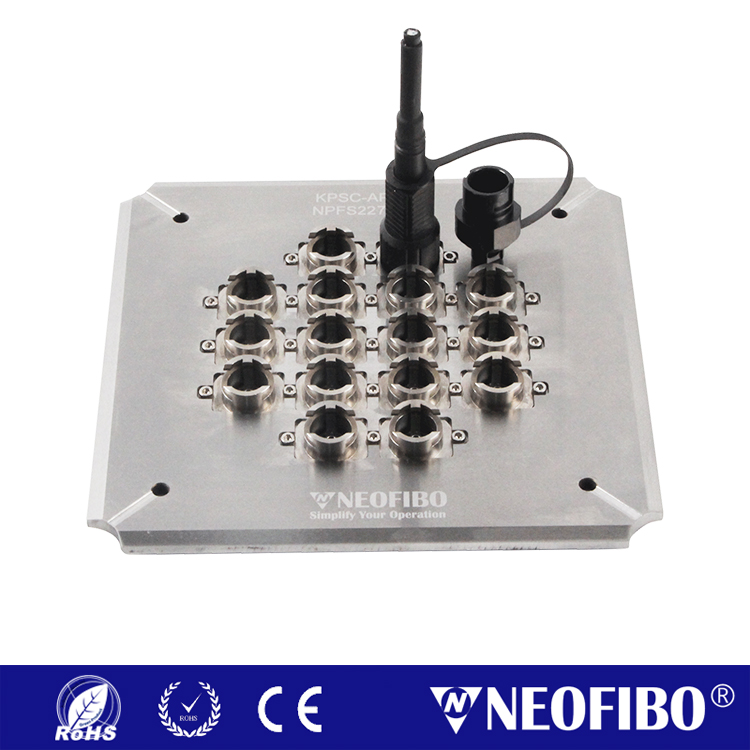

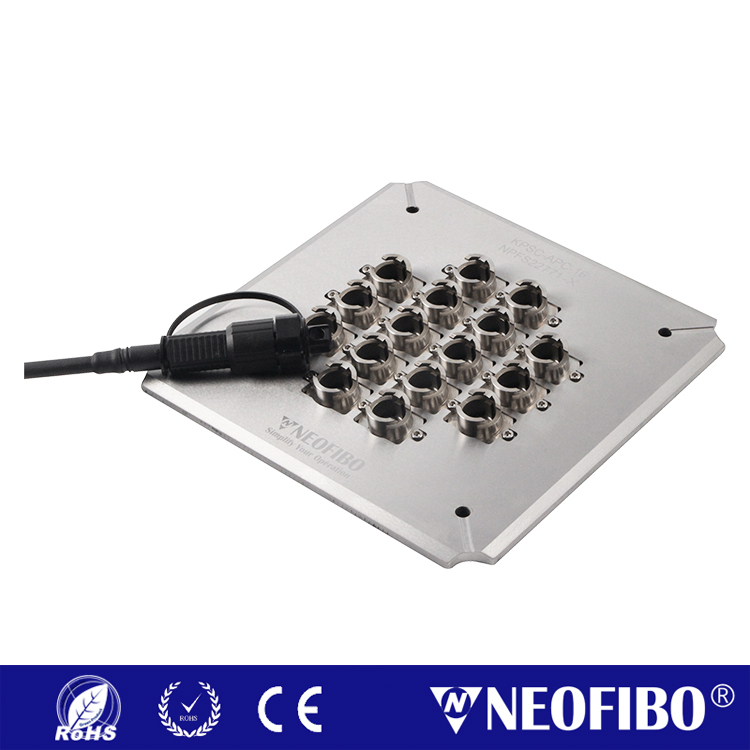

| 15 | SC waterproof head fixture* | SC-APC-20IPC* | 6 | Pcs |

| 16 | Single core fiber endface interferometer | SANA2 | 1 | Set |

| 17 | 400/200 Dual Rate Endface Inspector | FK4-420P | 4 | Set |

| 18 | Single Channel Winding Insertion Loss Tester | ILRL-6001 | 2 | Set |

| 19 | Tangle-Free Insertion Loss Meter | ILRL-6001M | 2 | Set |

| 20 | Four-channel red light source | VFL-4C | 1 | Set |

| 21 | Dual-port fiber stripping pliers | NFS-2 | 10 | PCS |

| 22 | Miller Aramid Scissors | KS-1 | 10 | PCS |

| 23 | Fiber Optic Cutting Pen | OFS-02 | 10 | PCS |

| 24 | Fiber optic connector crimping pliers | CRP-2652 | 4 | PCS |

Note: Customized products are marked with ”*“.

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.