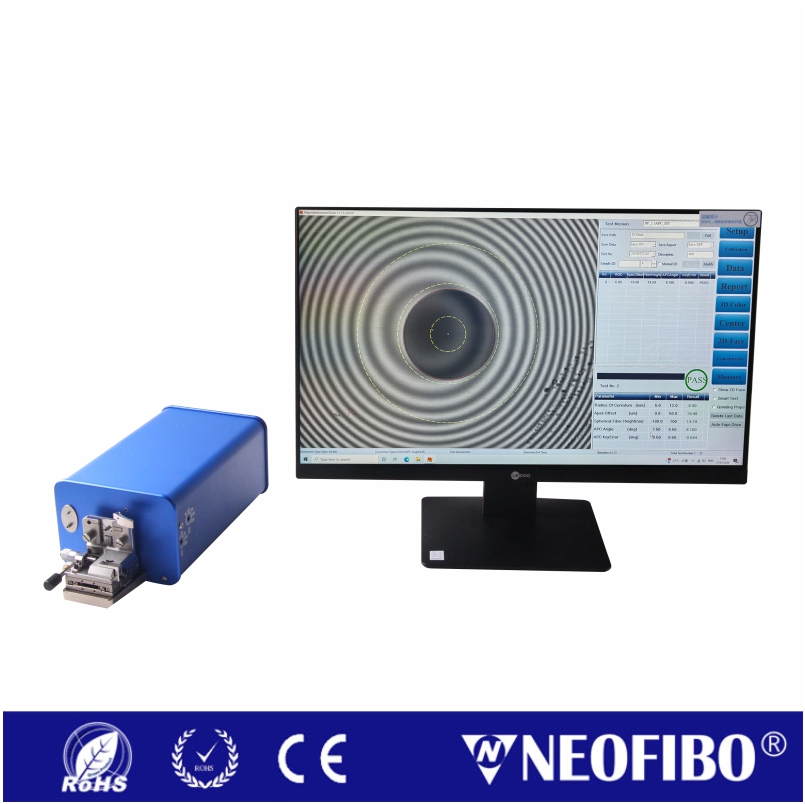

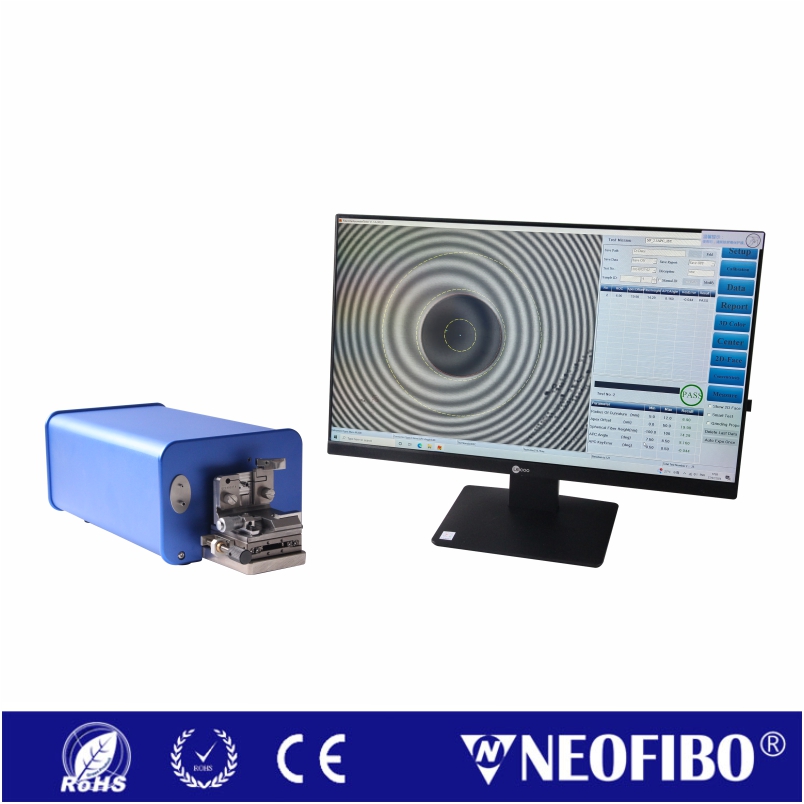

Neofibo Single Fiber End-face Interferometer,FI-SFC

Single Fiber End-face Interferometer,FI-SFC

Product Desperation:

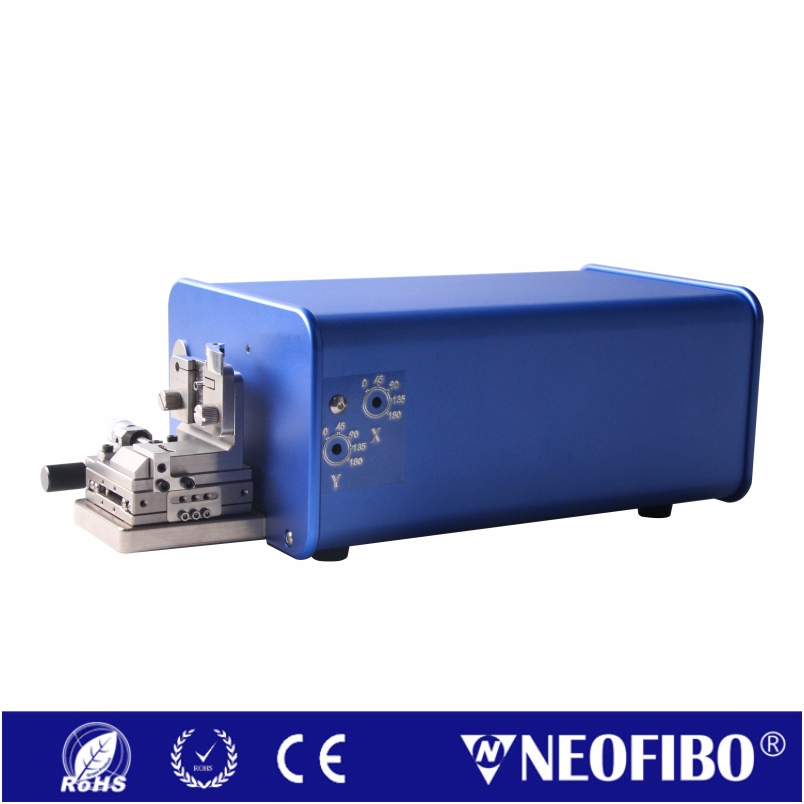

FI-SFC Fiber end-Face Interferometer is a non-contact, manual focusing, automated interferometer,that uses micro-imaging technology combined with Michelson interferometry and precision phase-shifting algorithms to accurately and rapidly test the three-dimensional contours of microscopic surfaces. All single core fiber connectors can be tested, including radius of curvature, fiber height, vertex offset, APC angle and key angle difference digital indicators. In addition, the device provides end-face inspection, assisted ferrule concentricity, grinding parameters and other IEC parameters to help users provide feedback on their grinding and mounting processes. The SMA905 core fixture can be customized for testing fiber optic connector end-face morphology in the laser and medical industries to control the geometric parameters of the morphology.

Key Feature:

- Extremely fast test efficiency: the device in ordinary mode, a single test in about 0.5 seconds, in the “high-speed mode”, a single test time of 0.3 seconds. It is one of the fastest interferometers on the market. The unique fixture design makes it easy to find the interference signal every time the sample is inserted, eliminating the need for frequent focusing. After the test is completed, it can automatically restore high-definition three-dimensional three-dimensional map and curve fitting diagram, users can intuitively observe the connector surface morphology.

- Intelligent sensor test function:the equipment adopts advanced optical sensor design, accurate and error-free judgment of the sample into the fixture locking. Real-time start test, to ensure the test efficiency under the premise of reducing the possibility of non-standardized operation.

- Real-time switching of end-face interferometry:The device adopts a unique optical circuit design, which can automatically and seamlessly switch between interferometry mode and end-inspection mode. Enables the user to complete two tests in a single inspection.

- Ferrule End-face Test: The machine can also be used to test the core face in three dimensions, including radius of curvature, vertex offset, and to calculate roughness, scratches, etc. This function can be used by core manufacturers to control the end face grinding of their ex-factory products. This feature can be used by insert manufacturers to control the end-face grinding of their shipped products and to improve the insert manufacturing process.

- Concentricity test:the device utilizes the principle of end-face imaging, can also be used to assist in testing the concentricity of connectors and inserts. Can be used for connector manufacturers of incoming material testing.

- Connector core function: the use of fiber-optic imaging principle, test the core of the circle and detect the amount of beating in the process of rotation to achieve the core function. Favorable to improve the interchangeability and optical performance of connectors, and reduce insertion loss.

- Perfect data report storage: the equipment can automatically output test data and reports during the test process, which is convenient for users to archive and manage.

Specification:

| Measurement items | Measurement range | Repeatability | Reproducibility |

| Radius of curvature(mm) | 3~∞ | ±0.03 | ±0.05 |

| Fiber height (nm) | -160~160 | ±2.0 | ±3.0 |

| Vertex Offset (um) | 0~500 | ± 1.0 | ±2.0 |

| APC angle (deg) | 0~11 | ±0.01 | ±0.02 |

| APC Bonding Error (deg) | ± 1 | ±0.02 | ±0.03 |

Standard Configuration:

| No. | Product Name | Model | Unit | Qty |

| 1 | Fiber End-face Interferometer | FI-SFC | Set | 1 |

| 2 | Computer mainframe | LENOVO-PC | Set | 1 |

| 3 | 2.50mm Ferrule fixture | HDR-GSY-SCP | Pcs | 1 |

| 4 | 1.25mm Ferrule fixture | HDL-GSY-LCP | Pcs | 1 |

| 5 | SC Connector Positioning Plate | DWP-GSY-SC | Pcs | 1 |

| 6 | FC Connector Positioning Plate | DWP-GSY-FC | Pcs | 1 |

| 7 | LC Connector Locator Tabs | DWP-GSY-LC | Pcs | 1 |

| 8 | 2.50mm Ferrule Aligner | JZJ-GSY-2.50 | Pcs | 1 |

| 9 | 1.25mm Ferrule Alignment Fittings | JZJ-GSY-1.25 | Pcs | 1 |

| 10 | SC APC Reference | CKJ-SCAPC | Pcs | 1 |

| 11 | Operator’s manuals | OG-FI | Pcs | 1 |

| 12 | Software | USB flash drive or CD-ROM | Pcs | 1 |

Options list:

| No. | Product Name | Model | Unit | Qty |

| 1 | SMA905 Ferrule Fixture | HDR-GSY-SMA | Pcs | 1 |

| 2 | SMA905 Ferrule Calibrator | JZJ-GSY-SMA | Pcs | 1 |

| 3 | SMA905 Ferrule Fixture | HDR-GSY-SMA | Pcs | 1 |

| 4 | SMA905 Ferrule Calibrator | JZJ-GSY-SMA | Pcs | 1 |

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.