Production Line for Fiber Optic Patchcord

Neofibo fiber polishing solution

Why do you manufacture fiber optic patch cord by yourselves?

1.The total cost is rising in China.(human cost, material cost & administration cost).

2.Lead time is longer than your expectation.Even a sample order, you will spend 2 ~ 3 week receiving it. Only 3 days lead time for local manufacture.

3.Freight charge is higher. Almost shipping all the order by air.

4.Difficult to control the quality requirements.

Neofibo is a professional patch cord production team that can produce machines for manufacturing patch cords and provide fiber polishing solutions that conform to your production standards.

If you are buyer of fiber optic patch cord, you must feel the same way with us.

- Cutting cable: Cutting cable into customized length, such as 1 mtr / 2 mtrs / 3 mtrs / 5 mtrs / 10 mtrs etc. Coiling cable into Φ100 mm circle.

- Inserting Component: Insert Boot, Ring, Eyelet, Stopper, Spring onto cable.

- Stripping Fiber: Stripping outer jacket, buffer and coating into fixed length, and cut kevlar.

- Mixing Epoxy: Mixing 353ND Epoxy Part A & Part B according to 10:1 then pour the mixed Epoxy into syringe or glass test tube, and seal it.

- Cleaning Bubble: Pour mixed epoxy into syringe / glass test tub or small glass breaker. Put the sealed 353ND epoxy syringe into centrifuge machine.

- Injecting Epoxy: Pour the epoxy into auto injecting syringe if you injecting Epoxy with machine.

- Inserting Fiber: Insert stripped fiber into ceramic ferrule with epoxy.

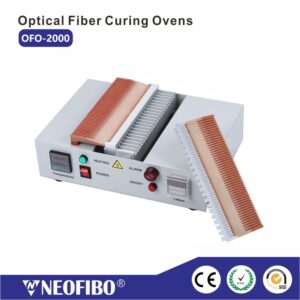

- Epoxy Solidifying: Solidifying eposy after inserting fiber.

- Assembling and Crimping: Put Kevlar between stopper and crimp eyelet, then put slitted jacket between eyelet and ring.

- Crimping Machine: Crimp Kevlar onto stopper,Crimp jacket on eyelet.the connector is able to withstandtension after crimping.

- Polishing: Install assembled connectors into polishing fixture.Polishing the connectors according the procedures.Contact us, we can customize the fiber polishing solution for you.

- 3D Testing: Clean polished connectors and test the geometry sizes of polished ceramic ferrules. If you are starter, interferometer is not the necessary equipment for you.

- 1st Endface Inspection: Inspecting the end face quality of polished connectors.

- ILRL Testing:

Connector Type SM, UPC SM, APC MM, UPC Insertion Loss ≤0.30dB ≤0.30dB ≤0.50dB Return Loss ≥55dB ≥60dB ≥30dB - VFL Inspection: Inspecting the damage on cable and connectors with VFL.

- 2nd Endface Inspection: Re-inspecting end-face quality after 3D test, ILRL test and VFL test.

- Packing & Label: Put the tested patch cord into PE bag and paste label onto PE bag.Mark connector type / cable length / IL Value / RL Value.

3 questions you want to know:

- How much does it cost to establish a starter line?

- How many operators do you need at least if you start the production line?

- How long does it take to make operators skillful?

If you want to know the answers to these questions, please feel free to contact us.We can provide a fiber polishing solutions to help you produce a high-quality patch cord