Precision Meets Versatility: Selecting a Fiber Polishing Machine for All Connectors

In the manufacturing of fiber optic patch cords and during network deployment and maintenance, selecting a polishing machine that offers both high polishing precision and compatibility with multiple connector types (such as LC/SC/FC/MPO, etc.) is crucial for enhancing efficiency and ensuring connection quality. The selection process should focus on two core criteria: “multi-type compatibility” and “high-precision control,” combining technical specifications with actual operational requirements for a comprehensive evaluation.

I. Equipment Compatibility: The Cornerstone of Success

First, confirm whether the equipment supports polishing fiber optic ferrules or connectors of various specifications. Taking Shenzhen Neofibo Technology Limited.’s products as an example:

- The FPM-5000 programmable fiber polishing machine is suitable for SC, FC, ST, E2000, MU, LC, MPO, and other connectors, with particularly outstanding polishing results for MPO/MT connectors;

- The NPL-2000D intelligent foursquare pressure polishing machine accommodates SC, FC, ST, E2000, MU, LC, MPO, SMA, and other types, commonly found in patch cord manufacturing workshops;

- The intelligent lift pressurized control polishing machine also supports the aforementioned connectors but is primarily used for polishing higher-precision optical components like light beams and endoscopes.

- The RP-1800 fiber connector end-face polishing machine , paired with various connector fixtures, enables rapid field repairs for outdoor applications.

All these models feature modular designs, allowing quick fixture changes on a single platform. They cover mainstream connector types without external modifications, significantly enhancing equipment versatility and operational flexibility.

II. The Critical Role of Fixture Precision and Adaptability

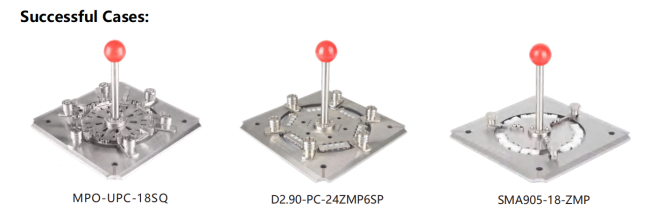

The precision of connector fixtures is also one of the primary factors directly affecting polishing quality. High-quality grinding fixtures should feature a high-precision clamping system, ensuring clamping parallelism error ≤0.01mm to prevent polishing angle deviation caused by fixture misalignment. For example, Neofibo’s foursquare pressurized master-slave disc polishing fixture structure supports rapid switching between various ferrules such as MT, LC, and SC. This design ensures stable clamping while enhancing operational efficiency for multi-type adaptability.

III. Polishing Precision and Process Control: The Heart of Quality

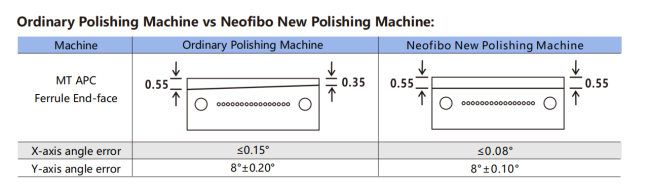

The mechanical precision of the equipment itself, combined with the process program, jointly determines the final polishing outcome. The turntable flatness should be ≤0.01mm to prevent fiber protrusions or uneven end faces. Additionally, the equipment should support multi-stage programmable polishing processes (such as de-gumming, coarse grinding, fine grinding, and polishing), with configurable parameters for different end face types like PC/UPC/APC.

IV. Intelligent Operation and Enhanced Stability for Improved Efficiency

Modern high-precision polishing machines typically feature parameter storage and recall capabilities, enabling the saving of independent polishing programs for different connector types to minimize human-induced setup errors. Real-time status monitoring and counting functions also facilitate timely tracking of polishing progress and consumable lifespan, further ensuring process consistency and reducing defect rates.

V. Summary

When selecting a high-precision fiber polishing machine compatible with multiple connector types, systematically evaluate its “modular compatibility,” “fixture and mechanical precision,” “programmable process control,” and “intelligent operation capabilities.” By referencing proven brands like Neofibo’s technical solutions and actual parameters, and balancing compatibility, precision, and efficiency according to your specific application requirements, you can meet the increasingly stringent connection quality demands in the fiber optic communications field.

For more product details, please call our hotline or email us for inquiries about this equipment.

Sales Hotline: 0755-86223060

Tel:13510636654 (Mr. Yang, same number for WeChat)

18926751600 (Ms. He, same number for WeChat)

Email: info@fibrekits.com, sales@fibrekits.com

Web: https://www.fibrekits.com