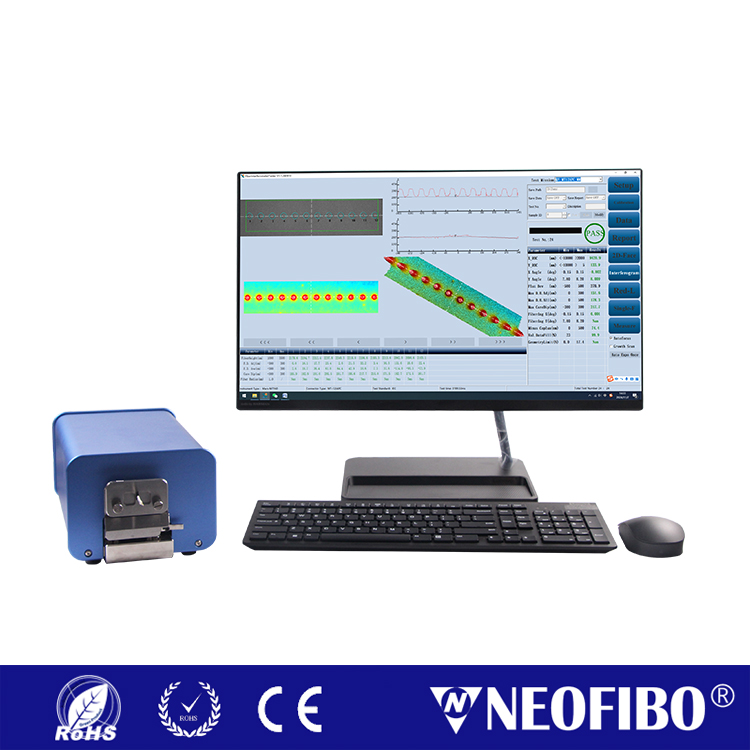

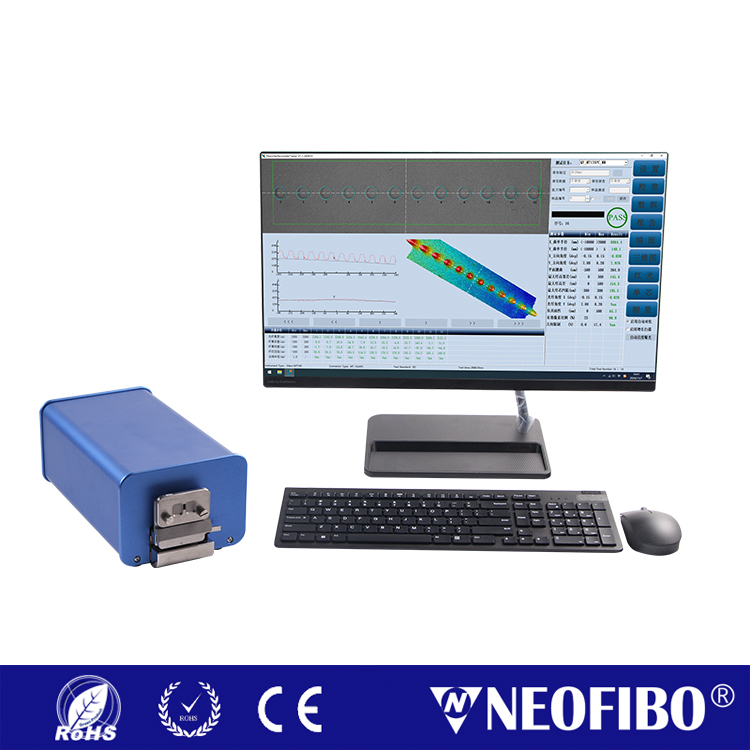

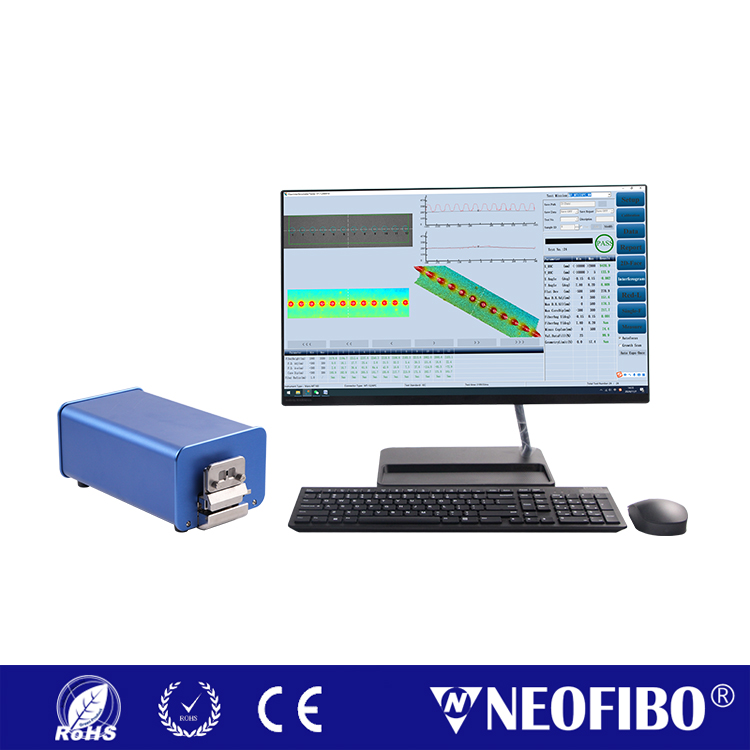

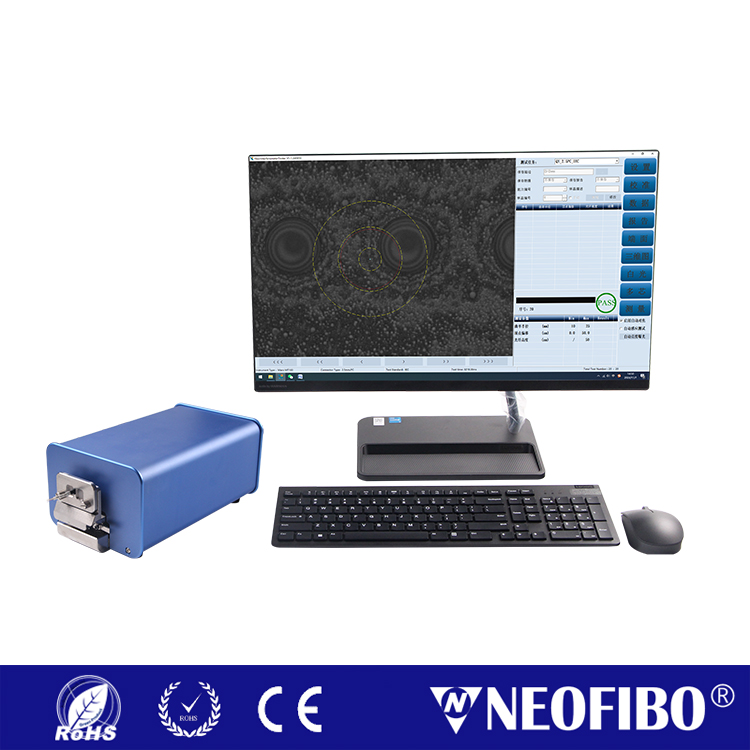

Single or Multi Fiber End-face Interferometer ,FI-MT

Single or Multi Fiber End-face Interferometer ,FI-MT

Place of Origin: China

Model:FI-MT

Description:

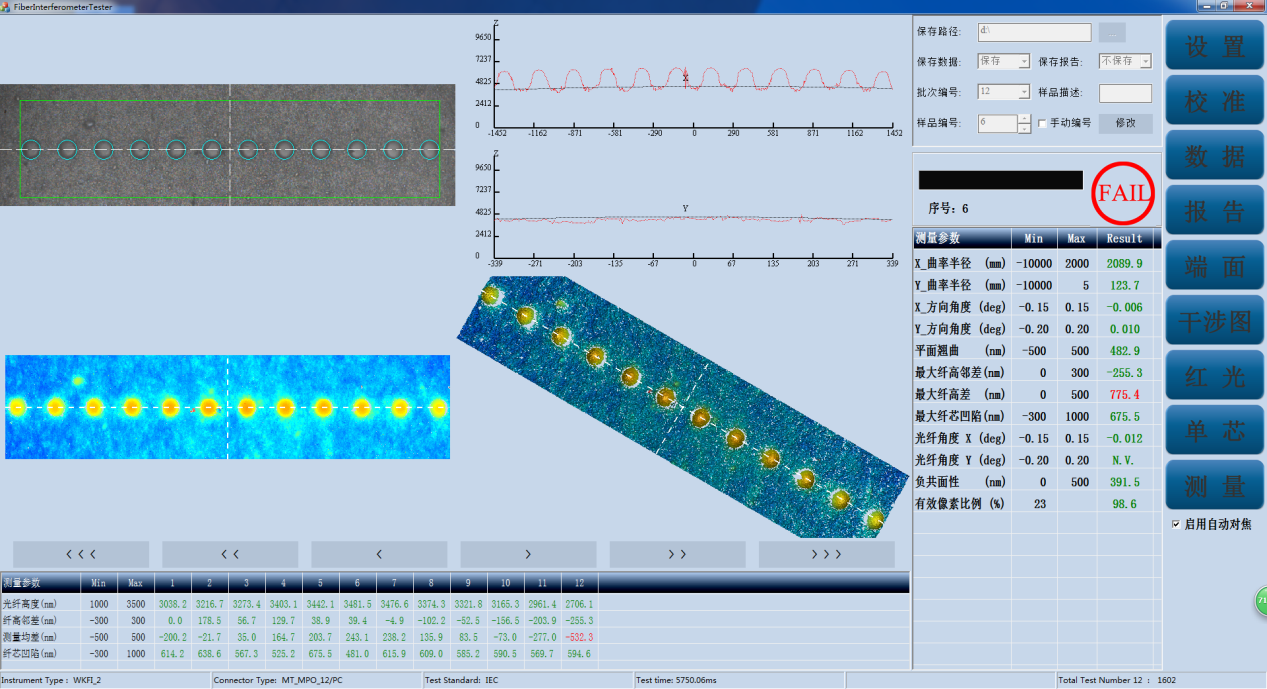

FI-MT single multi fiber end-face interferometer is a cost-effective, autofocus, non-contact fiber optic end-face interferometer. The product uses white light, red light interference principle to restore the geometry of the fiber end-face and then calculate the technical parameters, in the measurement of MT, MTRJ and other multi-core fiber optic connectors on the basis of compatibility with the single-core FC, SC, ST, LC, MU and other conventional connector measurements, one-key switching, the detection process of focusing, calibration, measurement are automatically completed through the software.

Key Features:

FI-MT type single multi-core integrated fiber end-face interferometer is mainly divided into two parts: interferometer mainframe and special measurement software. The device is mainly characterized by the following:

(1) Measurement of a wide range of samples, with a large number of cores and fast speeds

The FI-MT interferometer offers extremely high resolution and a large field of view, with a test area of up to 3.3 mm X 2.6 mm. The software can now perform fast measurements on multi-pole connectors of up to 72 cores, and 12-pole connectors in as little as 5 seconds. Whether for process development or mass production, the FI-MT interferometer fixtures include MT/MPO insert fixtures, MT/MPO finished fixtures, MTRJ insert fixtures as well as SC general-purpose single-pole fixtures and LC general-purpose single-pole fixtures, which can satisfy the end-users’ requirements for single-pole and multi-pole connector measurements.

(2)Simple software measurement interface

FI-MT measurement software interface is intuitive and clear, easy to operate, and supports Chinese and English display. The software will automatically analyze and judge the data of the tested part, and reduce the geometric end face of the tested part to a three-dimensional diagram, giving 2D diagrams of the multi-core connector, section line diagrams, and single-core connector surface roughness diagrams, isometric diagrams, which is convenient for users to intuitively judge the condition of the connector’s end face under test. At the same time, it automatically generates test reports and test data reports in Excel file format, which is convenient for document management and printing. In addition, single multi-core software switching just click a button, the software will automatically read the internal storage information according to the situation and convert the light source, standards, measurement mode and other information. To do a real one-button switch.

(3)Convenient and intuitive hardware operation

FI-MT interferometer only needs to connect the power cord and USB cable to complete the hardware connection. The interferometer fixture adopts taper angle locking positioning, no need to do any hardware adjustment after installing on the interferometer, through the software can complete the optical fiber image center positioning work. PC measurement mode and APC measurement mode conversion does not need to replace the fixture, and do not need to re-calibrate the interferometer, as long as the angle of the operating platform adjusted to the corresponding position can be directly measured.

(4)Fully automatic calibration, focusing and measurement functions

FI-MT interferometer has built-in automatic calibration module, the whole process is simple and fast. The software has detailed text and picture prompts wizard to make the user’s calibration more convenient, fast and intuitive. After the calibration is completed, the measurement software will automatically analyze the deviation value of the hardware, and click the “Confirm” button, the software will automatically compensate the deviation value of the hardware, so that the user no longer needs to make manual adjustments to the hardware to achieve the purpose of calibration. The autofocus function eliminates the need to manually adjust the focus and allows the user to quickly and automatically find the clear interference fringes and move the scanning start position accurately through the one-button operation of the software to complete the entire measurement process. In addition, the FI-MT interferometer is equipped with coarse and fine adjustment buttons for manual focusing, which increases the flexibility of use.

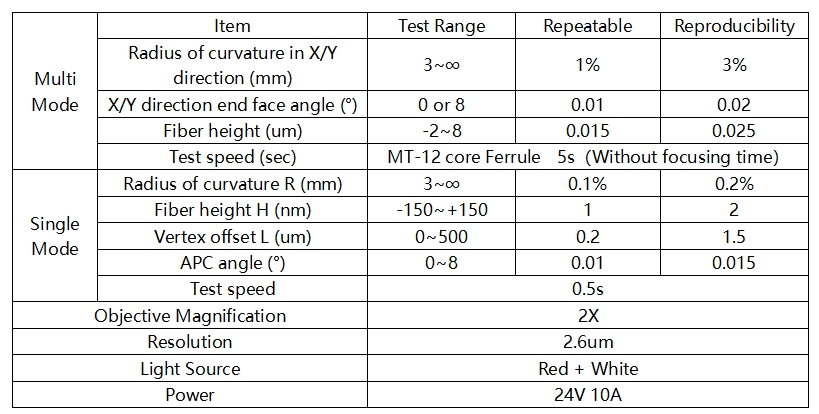

Specification:

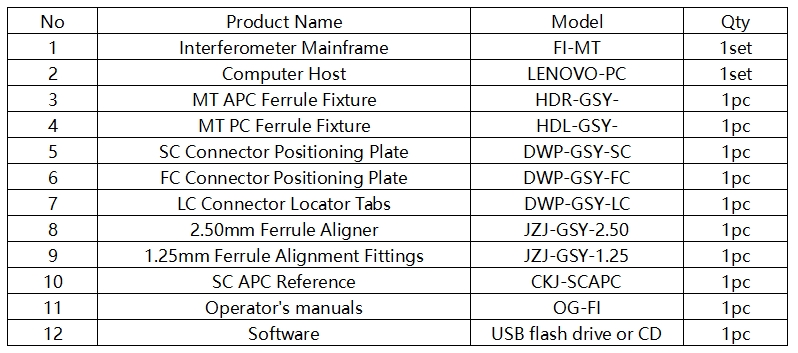

Standard Configuration:

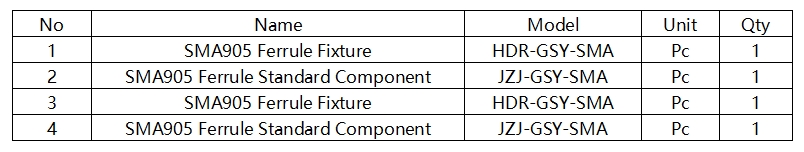

Options list:

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.