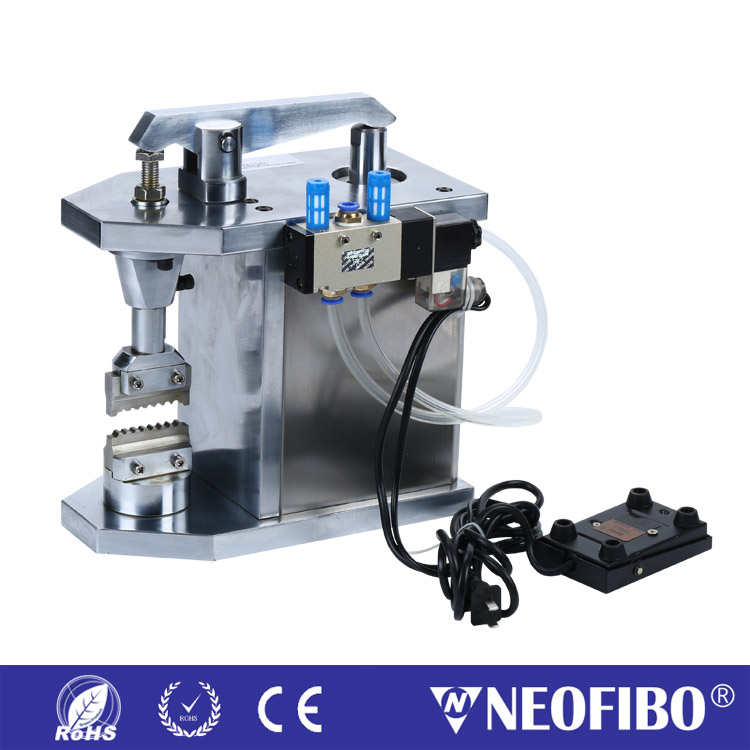

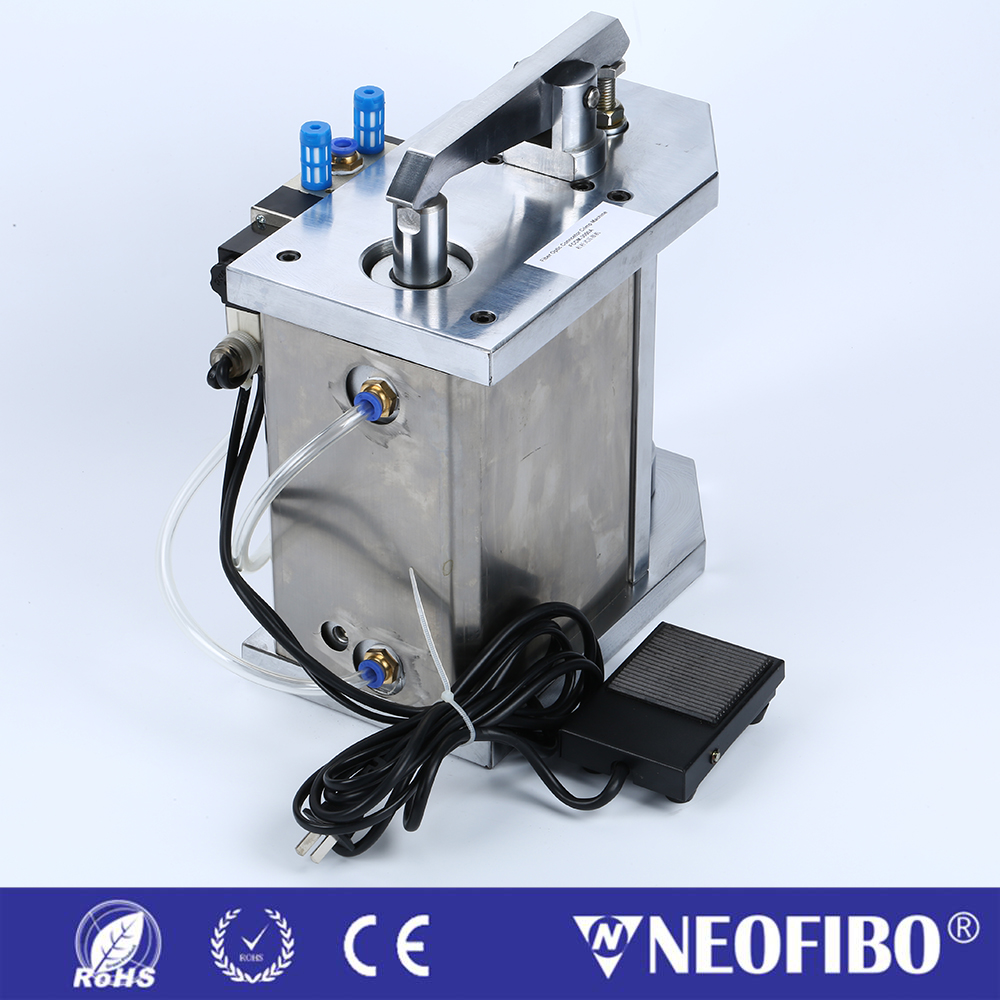

Fiber Connectors Cripming Machine FCCM-3000A

Fiber Connectors Cripming Machine FCCM-3000A

Description:

FCCM-3000A Crimping machine is used for assembling fiber optic connectors / ceramic ferrules and fiber optic adapters. Pressure of the machin is adjustable, and it is available for different kinds of fiber optic connectors (Such as FC, ST, SC, MU, LC, E2000, LX.5 and so on). Easy to handle, High quality and High efficiency.

Model: FCCM-3000A

Place of origin: Shenzhen

Description:

1.FCCM-3000A Crimping machine is used for assembling fiber optic connectors / ceramic ferrules and fiber optic adapters.

2.Pressure of the machin is adjustable, and it is available for different kinds of fiber optic connectors (Such as FC, ST, SC, MU, LC, E2000, LX.5 and so on).

3.Easy to handle, High quality and High efficiency.

Key Features:

1.Designed for fiber connector crimping and assembly.

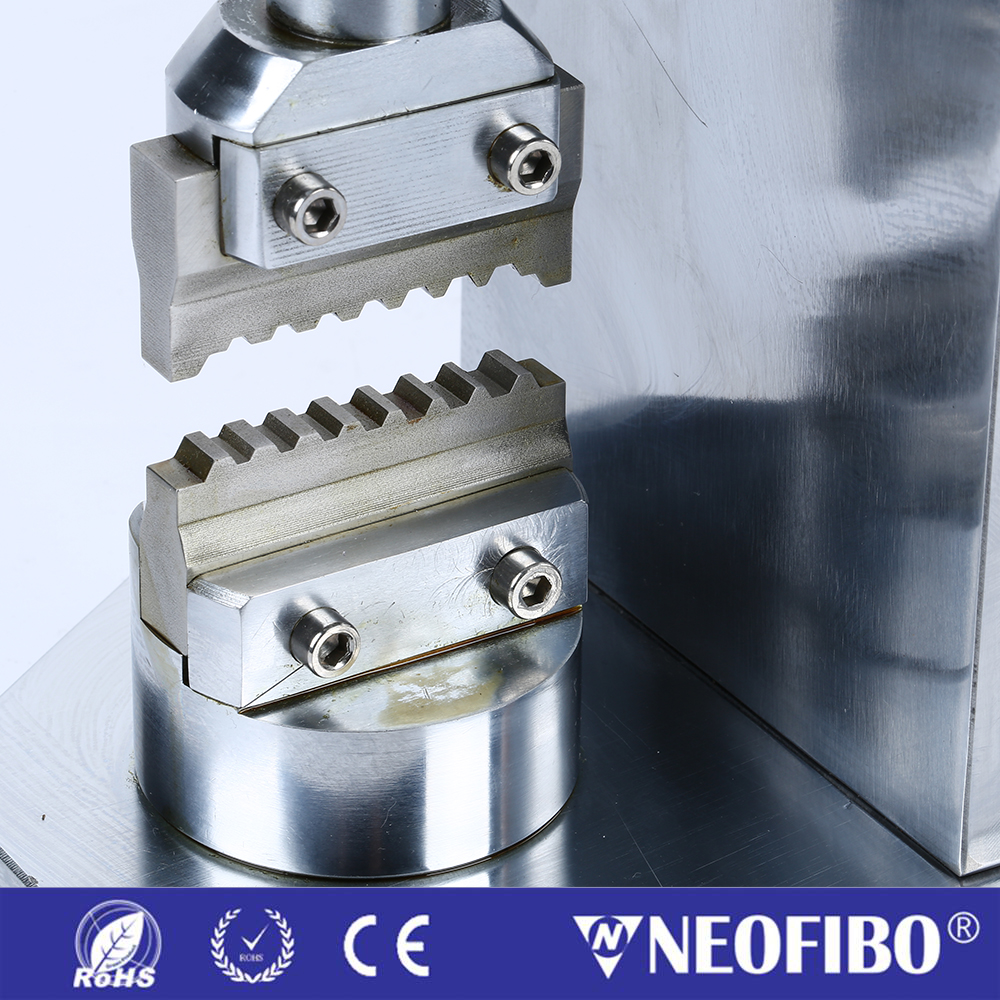

2.Precision Hex size for Crimp die for.

3.Applicalbe to SC/FC/E2000/MU/LC connectors.

4.Provide optional MPO crimp die.

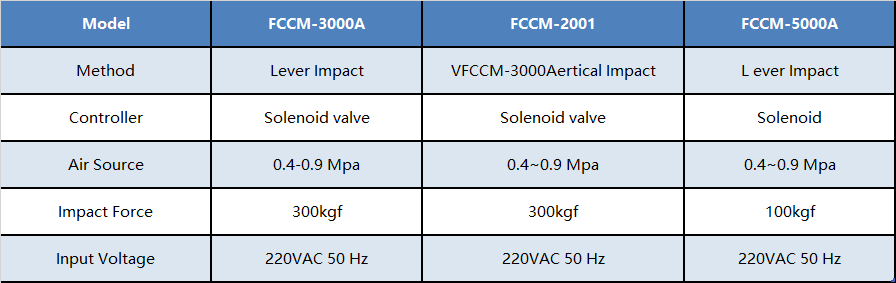

Specifications:

Safety Tips:

(1). When stepping on the foot switch, keep hands and other part of body leaving the crimping mould.

(2). Please Keep it “Power Off” if the machine will be not used.

How To Use It?

(1). Get through the air pressure and make it turn on, then adjust the pressure to point at 0.4 on the dial.

(2). Before crimping, put different connectors into different mould slot.

Slot order From front to back,

The first is fit for FC/SC3.0;

The second is fit for LC/ST3.0 and FC/SC3.0;

The fourth is fit for LC/MU2.0.

(3). Turn off the power and cut down the air pressure when you don’t intend to use it.

Maintenance:

(1). Clean the crimping slots and machine after you finish crimping, examine whether the slots have been damaged. If the slot was damaged, please change the crimping mould.

(2). If the crimping machine will not be used for a long time, put it in the ventilated and dry place to prevent the mould getting rust.

(3). The crimping mould will get abrasion if it is used for a long time. The body of crimping machine have one year warranty. If the machine is out of guarantee, we still provide maintenance and repair service. If you have problem to use it, please send email to sales@fibrekits.com.

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.