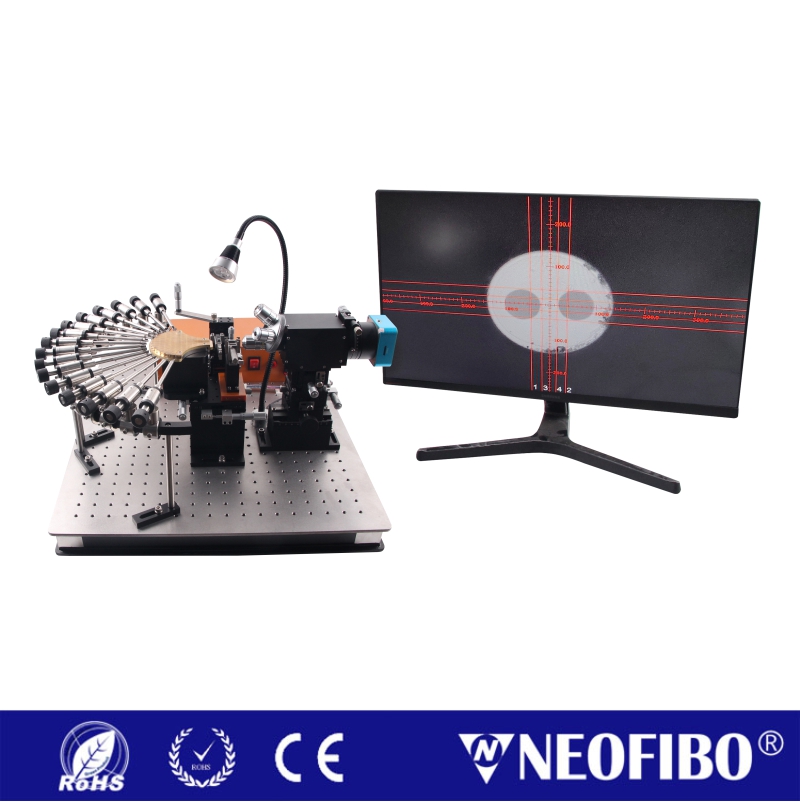

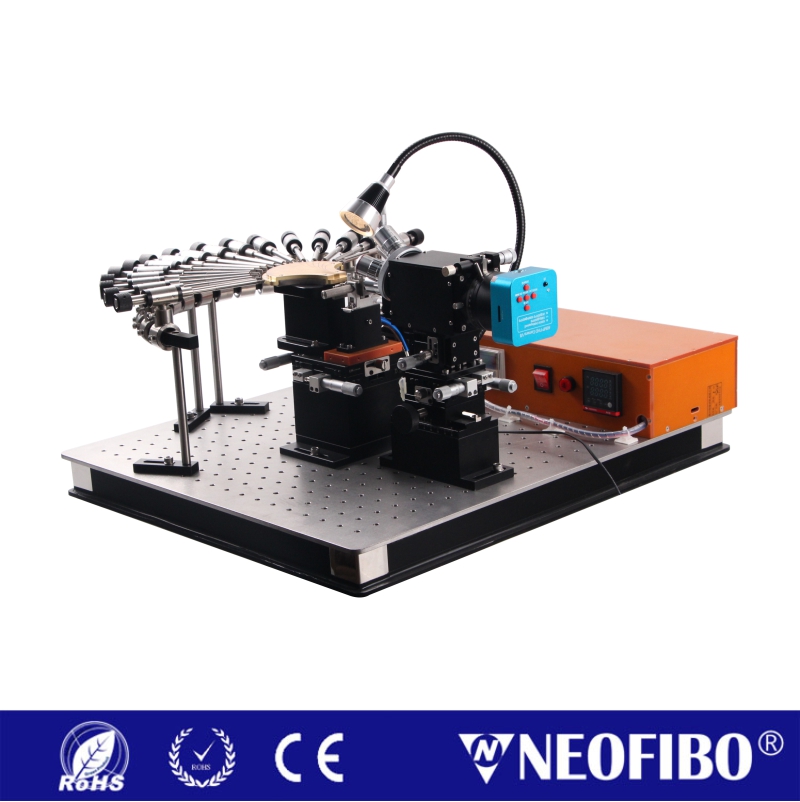

Multi Polarization Maintaining Fiber Alignment System;PMF-421P-FA16(FA+MT)

Multi Polarization Maintaining Fiber Alignment System

PMF-421P-FA16(FA+MT)

Product Description:

In response to customer demand, Neofibo has designed an all-in-one FA and MT fiber alignment system by integrating FA and MT alignment features, which can complete the alignment of different products by simply replacing the tooling and achieve multi-purpose use without affecting the accuracy of the alignment.

This equipment adopts high-definition camera and internal/external light source to ensure clear imaging of the fiber end-face, ensure accurate alignment of the catenary, efficient dispensing or replenishment operation, and finally complete the heating and pre-curing. Customized horizontal and vertical grid lines ensure that the angular deviation after alignment is far less than ±3 degrees. Its excellent alignment accuracy effectively reduces optical signal transmission loss.

Model: PMF-421P-FA16(FA+MT)

Place of Origin: Shenzhen, China

Key Feature:

- Suitable for 16-core FA fiber array or MT PM fiber alignment, which is efficient in operation and multi-purpose;

- Can realize heat curing or UV curing;

- High-definition camera imaging 100-800 times magnification, effectively control the alignment angle is less than ± 3 degrees;

- Multiple horizontal and vertical grid lines to ensure fast and slow axis consistency;

- 3-axis adjustment frame precision control, fine-tuning accuracy ± 0.01mm;

- Internal and external light source to ensure clear end-face imaging of the PM fiber;

- 600x500mm optical platform is convenient for system expansion;

- After the catenary alignment is completed, it can be heated and pre-cured or UV cured directly in the fiber ferrule or capillary tube;

- Spindle adjustment angle 0~360 degrees.

Specification:

| Model | PMF-421P-FA16(FA+MT) |

| Function | FA or MT PM fiber alignment, in-line curing, end-face inspection |

| Applicable ferrules | Standard: FA fiber array, MT ferrule

Options: FC, SC, LC, mini MT ferrules, glass capillary locator, dual-core PM fiber capillaries |

| Curing Method | Heating or UV curing |

| Curing Method A | 85~150°C adjustable, 4~6 minutes |

| Curing method B | UV curing, 2~3 minutes |

| Heating power | 80~100W, 220V, 50Hz |

| Countershaft rotation angle | 0~360°adjustable |

| Number of countershaft rotators | 16 |

| Countershaft rotator | Four-axis adjustable |

| FA insert holder | One axis adjustable |

| Imaging system | Three-axis adjustable |

| Illumination light source | Built-in light source and external light source |

Standard Configurations:

| No. | Description | Qty |

| 1 | CCD camera focusing system | 1set |

| 2 | Heating timing curing system | 1set |

| 3 | 250/900um fiber optic rotator | 1set |

| 4 | LED external light source | 1set |

| 5 | 24 inch Samsung LCD monitor | 1set |

| 6 | 12V 5A Power Adapter | 1pc |

| 7 | AC Power Cord | 1pc |

| 8 | Built-in light source control switch cable | 1pc |

Order Information:

| No. | Description/Model | Qty | Remark |

| 1 | Multi Polarization Maintaining Fiber Alignment System, PMF-421P-FA16 (FA+MT) | 1set | standard |

| 2 | PMF-FA-DWJ, FA Ferrule Positioning Fittings | 1pcs | standard |

| 3 | PMF-MT-DWJ, MT Ferrule Positioning Fittings | 1pcs | standard |

| 4 | PMF-200PL, Capillary Grinding Fixture In-Line Inspection | 1set | optional |

| 5 | PMF-SC-DWJ, SC Core Positioners | 1pcs | optional |

| 6 | PMF-FC-DWJ, FC Ferrule Positioning Fittings | 1pcs | optional |

| 7 | PMF-LC-DWJ, LC insert locators | 1pcs | optional |

| 8 | PMF-mini MT-DWJ, mini MT insert locators | 1pcs | optional |

Operation procedure (UV curing FA ferrule or 353ND adhesive heat curing MT/single core ceramic ferrule):

(1) Strip the fiber coating layer, 125um core length 22-30mm;

(2) Cutting fiber: use fiber optic cutting knife, fiber length 12-15mm;

(3) Dispensing: Inject an appropriate amount of 353ND epoxy glue into the fiber;

(4) Fixing the fiber: Fix the FA fiber on the positioning piece, with the dispensing window upward;

(5) Clean the fiber: use a cotton swab to clean the front end of the fiber, remove dirt, clearly visible panda eyes;

(6) Alignment axis: the FA fiber to keep the polarization maintaining rotation of the alignment axis, the panda’s eye placed in the correct position, fixed fiber position, to prevent rotation after the alignment axis, to complete the next step after fixing the alignment axis;

(7) Pre-curing: turn on the pre-curing switch, heating 5-10 minutes initial curing 353ND glue;

(8) Fully cured: the pre-cured ferrule and connectors placed in the curing oven for a full 15 minutes at 120 degrees heat curing;

(9) Assembly: the cured ceramic ferrules will be assembled into a finished connector and complete the crimp, FA ferrules do not need to be assembled directly mounted on the disk grinding;

(10) Polishing: through 4~5 polishing to complete the fiber end-face polishing;

(11) 3D test: as needed to detect the connector 3D geometric parameters, if not required, may not test;

(12) End-face inspection: check the fiber end-face for scratches / no white spots / no black spots / no edge breaks and other defects, if not judged as good;

(13) Extinction ratio and loss test: use special polarization extinction ratio tester and broadband light source to complete the test, according to customer standards to determine the product【OK】 and 【NG】.

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.