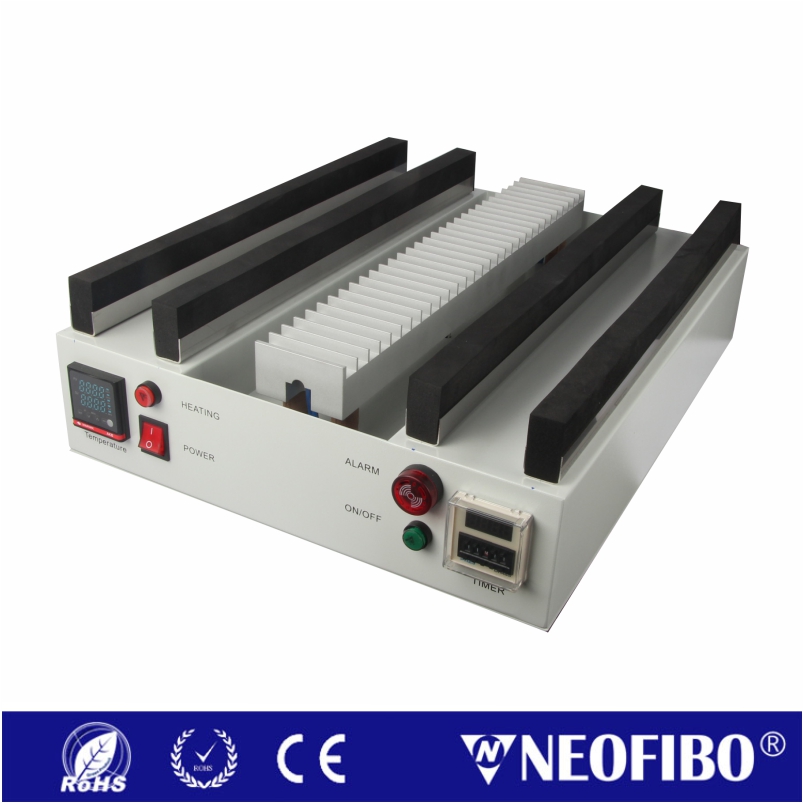

Fiber Optic Horizontal Curing Oven, OFO-3001

Fiber Optic Horizontal Curing Oven, OFO-3001

Description:

OFO-3001 Curing Oven is a type of universal curing oven for fiber optic connectors, it is available for general connectors (such as FC/SC/ST, MU/LC) after glue injecting. The heating board could contain 150-180 connector ferrules. There is indicator light, timer and temperature indicator. Simply operation and perfect solidified effect.

Place of Origin: Shenzhen, China

Model: OFO-3001

Key Features:

- Input voltage: 220 VAC 50 Hz, or 110 VAC 50 Hz;

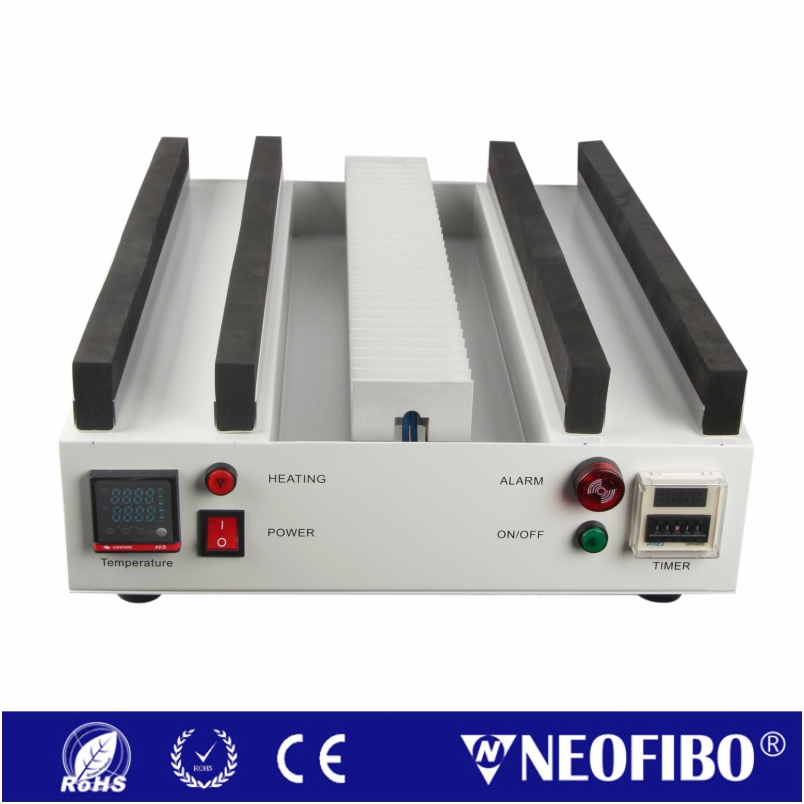

- Horizontal Heating Board, convenient for putting ferrules and connectors;

- High efficiency, 150-180 ferrules heating synchronously;

- Indicator shows temperature and time, high precision for temperature control;

- Automatically timing, and buzzer alarm reminding after time is up;.

- Without additional heating board, economic benefits.

Operating Instructions:

- Connected to single-phase power supply , 200V AC, 5A;

- Switch power to ON, the red LED lights;

- Program settings:

- Press SETUP to display the corresponding control button into the program settings, there are two settings, one for time, another one for temperature;

- Temperature control: set the curing requires constant temperature, press UP and DWON to add and subtract, display the desired temperature then press OK button to enter the time control. Factory settings default temperature: 100℃;

- Time control: when it shows entry time control, press UP and DWON to adjust the time, time is the time required for curing continued at a constant temperature. After adjusted the desired time, press OK to enter operation. Factory setting: 30 minutes;

- Curing, put the fiber connector into curing fixture, placing it in oven, heating board then covered with dust cover;

- Press OK, curing, curing furnace heating temperatures to the specified time, timer automatic timer, temperature should keeping constant, arrived at the designated time, curing oven stopped heating, curing cycle ends;

- If need cure again, time and temperature still stay the same then put connectors into fixture, placing it in oven, press AGAIN for next cycle of cure;

- If you need to change the time and temperature, enter SETUP, adjust them.

Technical parameters:

| Dimension (mm) | 510 x 400 x 470 |

| Weight (kg) | 11kg |

| Heating Temperature | 40 ~ 300 ℃ |

| Accuracy | +/- 3 ℃ |

| Input Voltage | 100~120VAC, 50Hz / 200-240VAC, 50Hz |

| Power Consumption | 800 W |

| Warm-up Time (approx.) | 15 min |

| Connector Type | 1.25 mm / 2.50 mm ferrule, FC/ST/SC/MU/LC |

| Capacity | 150-180 ceramic ferrules per cycle |

Remark:

This device uses high-precision integrated circuit design, with PID function, need to prevent too hard and damage components during the processing.

If the device has any abnormal display, please notify the supplier for repair in time.

Shenzhen Neofibo Technology Limited, founded in 2008 and based in Shenzhen, China, is committed to becoming a professional supplier of fiber optic polishing solutions. Our goal is to make our customers’ fiber connectivity more reliable.

Over the past 17 years, we’ve gathered a team of seasoned fiber optic professionals. Their expertise spans connector polishing and assembly, outside plant installation, transmission systems, datacom, CATV, and testing. Whether you’re a fiber optic scientist working on multi – gigabit, DWDM, or EDFA applications; a maintenance engineer for optical connecting systems; an outside plant contractor handling splicing and testing; a datacom manager dealing with multimode – to – single mode conversion; or an optical fiber component manufacturer in need of high – quality pigtails, consumables, and tools, Neofibo can provide you with proven solutions, products, and services.

Neofibo focuses on the field of fiber optic polishing solutions. We specialize in manufacturing fiber optic polishing machines, designing polishing fixtures for various optical fiber connectors, and offering complete polishing processes and materials for all types of fiber optic connectors.

We can also supply the full range of production equipment for fiber optic patch cords, including fiber optic polishing tools, end – face inspection microscopes, functional inspection and detection devices, raw materials like fiber optic cables and connectors, processing tools, and cleaning consumables.

Beyond products, Neofibo provides technical services and R & D support. We aspire to be your long – term, trusted partner.

What Does NEOFIBO Offer?

We provide a comprehensive range of high-quality fiber optic products, including patchcord production machines, polishing jigs (compatible with Seikoh Giken, Senko, Domaille standards, or custom-designed), polishing consumables, tools, cleaning supplies, tool kits, testing equipment, and splicing accessories. We are committed to delivering competitive pricing, superior quality, and fast turnaround!

What Are the Shipping Costs?

All listed prices are FOB Shenzhen. You may use your preferred courier; otherwise, we will arrange delivery via FEDEX, DHL, UPS, or another logistics provider (subject to confirmation), with shipping costs billed accordingly.

How Soon Will Goods Be Delivered?

– In-stock items: Dispatched within 1–2 business days after payment confirmation.

– Out-of-stock items: Estimated lead time of 3–10 working days.

How Can I Place an Order?

We offer three convenient ordering channels for our valued customers: online ordering, faxed order forms, or formal purchase orders sent via email.

What Is the Warranty Policy for NEOFIBO Products?

All NEOFIBO products (excluding consumables and items subject to normal wear and tear) come with a 1-year warranty from the date of purchase. For products with defects in materials or workmanship, NEOFIBO will, at its discretion, repair or replace the item—provided the product is returned to NEOFIBO (at the designated location) with prepaid shipping. This constitutes the exclusive remedy under the warranty.